Why is CMB’s COMBO Series a reference machine in the heat packaging of medium and large products?

Throughout our more than 35 years of history, the CMB COMBO is one of the heat wrapping machines most frequently requested by our customers when it comes to achieving high production rates of packaged products. This automatic film wrapping machine offers multiple advantages to those who incorporate it in their production plants and allows them to deliver their medium and large products with a polished finish that protects them from possible external agents that could damage them.

Automating the packaging system means betting on an increase in productivity and performance. Choosing one of CMB’s COMBO Series machines means choosing a heated packaging system that allows you to pack products of different sizes at the same time, without having to stop the automatic packaging process to change the film reels.

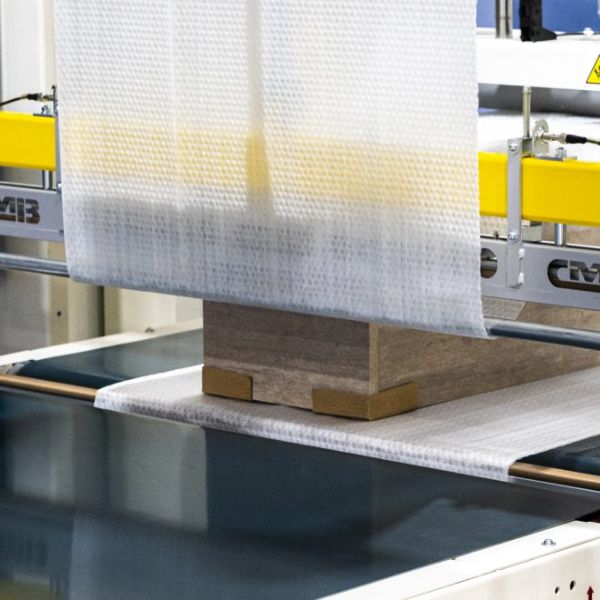

CMB’s COMBO series is equipped with a heat packaging system.

Broadly speaking, in the world of packaging, two main lines of packaging can be distinguished: cold and hot. Cold packaging is recommended in those cases where temporary packaging is required, preferably when the products have more or less regular and geometric shapes. This type of packaging uses stretch film and, depending on the degree of protection required, polyethylene bubble film, cellaire and cardboard can be added.

In the case of heat tunnel packaging, this is a more aesthetic and durable protection than that achieved by cold packaging and can be adapted to any product regardless of its shape. This is because the recyclable heat-shrinkable polyethylene film used in this type of packaging can shrink and adapt to any contour or shape when placed in the heat tunnel.

Advantages of packaging with one of CMB’s COMBO Series machines

Undoubtedly, one of the main advantages offered by CMB COMBO series machines is that they do not need to stop the packaging process to change the reels according to the size of the package. This machine has different stations where there are reels of different sizes and, depending on the dimensions of the package to be packed, it stops at one or another to be wrapped in recyclable heat-shrinkable polyethylene film. The machine’s conveyor belt then guides the product into the shrink tunnel so that, through the application of heat, the film shrinks and carefully fits the package, like a skin.

By not having to stop the machine and the packaging process to change film reels, much higher throughput can be achieved while avoiding waste packaging material.

CMB’s COMBO Series machines are designed in a modular way, therefore, they can be upgraded after start-up in order to meet the new needs of each company.

Minimize the environmental impact of your packaging with the COMBO Series from CMB

Every time any packaging machine with a heat application system is started or stopped, it generates a significant energy cost. In the case of the COMBO Series machines, which avoid having to stop the packaging process to change reels, this extra energy cost does not exist. Consequently, we can affirm that CMB’s COMBO Series helps to maintain sustainability and energy savings thanks to the uninterrupted packaging process of products of different dimensions.

Energy savings are not the only way in which CMB’s COMBO Series machinery helps to reduce the ecological footprint and the environmental impact of the carbon footprint. The fact of being able to work simultaneously with different reels of heat-shrinkable polyethylene film makes it possible to adapt and adjust the size of the film to the size of the package to be packaged, thus reducing the residual film surplus to a minimum.

And as if that were not enough, the packaging material used by CMB’s COMBO Series machines, heat-shrinkable polyethylene film, is 100% recyclable, so that the film left over during packaging can be given a new life, as well as the film that is discarded once it has fulfilled its function.

What other heat packaging options does CMB offer besides the COMBO Series line of machines?

In CMB’s packaging machinery catalog there are three models that offer packaging solutions with heat tunnel system. One of them is the COMBO Series, which we have shown above, but there are also the ERB and ERS Series.

- The ERB Series machines, or Barberán shrink-wrap machines, offer a packaging result that allows perfect visualization of the final product. They can pack a wide variety of products such as furniture, wood, aluminum, PVC, doors, windows, carpentry in general, mattresses, bed bases, all types of profiles, textile elements, etc.

- The ERS Series machines or overlap shrink wrapping machines are designed to offer high performance to those companies that need high production rates with products with very similar morphologies such as parquet, floorboards, etc. Throughout the packaging process, the package or product is only stopped once, which allows a very fast and agile packaging. Ideal for moldings, parquet and many other types of profiles, whether wood, aluminum. PVC, metal, etc.

Contact us and get the right model of CMB COMBO Series machine for you.

If after reading this article you are interested in contacting us to find out if it would be possible to integrate one of CMB’s COMBO Series machines in your production plant, please do not hesitate to do so. You can fill in the contact form that you will find on our website or, if it is more convenient for you, you can call us directly. CMB’s sales department will be at your disposal from the very first moment.