Hot packaging · Shrink wrap machine

Thinking of an industrial shrink wrap machine for your factory?

Hot packaging is distinguished from cold packaging by the techniques used during the packaging process and the different treatments given to the packaging material. Although it is always recyclable polyethylene, the reactions of this type of material, depending on whether heat is applied or stretching by mechanical traction, are totally different, and bring different types of finishes.

Having a CMB shrink wrap machine in the packaging process allows the polyethylene film to contract and adhere to the product being wrapped. In this way, it holds better, offers greater protection and a better aesthetic finish of the packaging, allowing even to see what is inside.

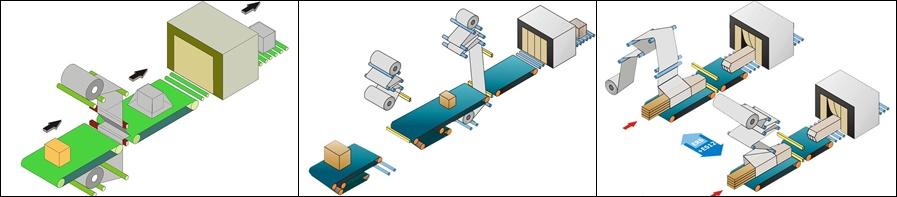

At CMB we have three different shrink wrap machines, which allow us to provide a solution to all the current needs of the industry, our customers and their products. All three packaging systems are suitable for a wide variety of products of different sizes.

ERB · Shrink wrapper

This is an industrial packaging machine designed to achieve high production rates, offering excellent packaging quality, along with a very competitive cost.

The film, when in contact with heat, contracts and creates a fastening wrapping effect on the product, protecting it and isolating it completely from dust, water and other external aggressions.

It is a machine of great robustness and efficiency, which only stops the product to be packed once during the entire process to weld the film, and which allows the packaging to be finished with personalized finishes, using plastics with specific characteristics, in different colors or even with the printed brand logo.

.

COMBO

This shrink wrap machine has been designed to wrap products intelligently, continuously and efficiently in equal parts. It is able to detect the dimensions of the product and then uses the appropriate reel and the right amount of film. It calculates the size of the product and makes the corresponding reel change, so that the packaging is perfectly adapted and the final result is optimal. This avoids using an excess of film, thus reducing costs and production is much faster.

ERS · Shrink wrap machine with bottom overlap welding

This industrial packaging machine uses a state-of-the-art process that will provide you with a long list of benefits. It is ideal for flat and regular shaped pieces, as well as for long lengths. Provides a very good display of the product; guarantees really high productions thanks to the fact that the transport table only makes one stop during the whole process; It is characterized by its robustness and by not having large maintenance tasks, being a very profitable investment for any industrial packaging plant.

If you have doubts or questions, you just have to contact our commercial department so that we can listen and advise you directly. We know that buying one of our shrink wrap machines can be a significant investment, so we want to help you in any way we can and guide you throughout the purchasing process, ensuring that the chosen equipment meets all your expectations.

Heat shrink packaging systems, also known as heat shrink systems, are useful in a variety of situations where you want to protect and stabilize products for transport and storage.

Here are some cases in which CMB recommends the use of heat shrink packaging systems:

- To protect products during transport: heat packaging can provide an additional layer of protection for products being transported, especially if they are irregularly shaped, fragile or delicate.

- To improve product presentation: heat packaging can improve the appearance of products by reducing the amount of air and void space in the package, which can make products look more attractive.

- To stabilize products: heat packaging can help stabilize products inside the package, which can prevent damage and reduce the amount of waste.

- To increase durability: heat packaging can help increase the durability of products by protecting them from the elements and preventing oxidation.

- To reduce package size: heat packaging can reduce package size, which can reduce shipping and storage costs.

- To comply with health and safety regulations: some products require special packaging to comply with health and safety regulations, and heat packaging systems can be an effective option to achieve this.

In heated packaging systems, low density polyethylene (LDPE) or high density polyethylene (HDPE) film is generally used as the material for the plastic wrap. LDPE is the most commonly used material because of its ability to stretch and form a uniform layer around the object being packaged. It is also tear and puncture resistant, making it ideal for protecting fragile products during transportation and storage.

CMB offers you three heat wrapping machines that adapt to multiple needs.

If you need a machine that can heat pack products of different sizes in an agile way without the need to change the film reel, the COMBO is your best option.

If you need a packaging machine that guarantees a perfect finish that allows you to see the product inside in an optimal way and is also fast packing, the ERB is the machine for you.

If your needs include fast and efficient packaging of flat pieces with regular shapes, the ERS, or overlap shrink wrapper, is the model to choose.

Industrial heat packaging refers to the process of applying heat to certain packaging materials to get them to soften and conform around an object or product to be packaged. This can be done using a heat packaging machine such as those offered by CMB.

The heat wrapping process generally involves the following steps:

- Place the object or product on the base of the heat wrapping machine where it is wrapped with heat shrink film.

- Activate the heat packaging machine to apply heat to the plastic film.

- The film will soften and shrink around the object or product.

- Once properly adjusted, the heat application is stopped and the packaged object or product is removed.

Industrial heat packaging is commonly used to protect and secure products during transportation and storage. This method of packaging is especially useful for products that are fragile or have irregular shapes, as the heat allows the plastic film to fit more tightly and adhere more firmly around the product.