Hot Packaging

COMBO · Shrink wrap packaging machine

It can beat them all … without interruptions

As industrial packaging machines manufacturers we are pleased to introduce you the COMBO series. This shrink wrap packaging machine is ideal in cases where it is necessary that products of different sizes are packed on the same packaging line and with the minimum number of stops in order to accelerate the process.

To avoid that the amount of surplus film is excessive, and to optimize its use, this shrink wrap packaging machine detects the dimensions of the product and selects the appropriate film reel for each one.

If you have doubts or need to ask us a question, you just have to contact our sales department by filling out the form found at this link. You can also call us by phone at (+34) 93 636 14 16 or send us an email to [email protected].

If you want to see all the shrink wrap packaging machine we have, just visit and spend two minutes on this section. We have been working as industrial packaging machines manufacturers for many years and we would like to help decide you to bet on our technology and our latest generation packaging systems.

|

|

|

- Designed always seeking maximum efficiency and consumable savings, the COMBO series is a perfect shrink wrap packaging machine for all those companies that need to work, at the same time, with products and objects of different sizes.

- It is capable of adjusting the consumption film by detecting the size of each product to be packed.

- As industrial packaging machines manufacturers, we can assure you that it is one of our most complete systems.

- As it is not necessary to stop the packaging process to proceed with the reel change, we can obtain a considerably higher production.

- The use of film reels of different sizes, depending on the dimensions of the package to be packed, allows considerable consumable savings.

- Thanks to its modular design, it can be incorporated later, allowing future extensions.

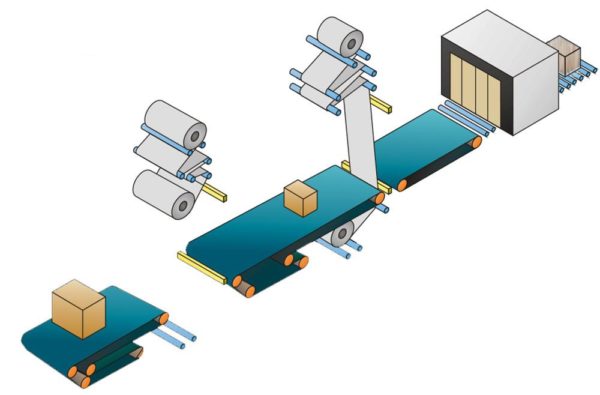

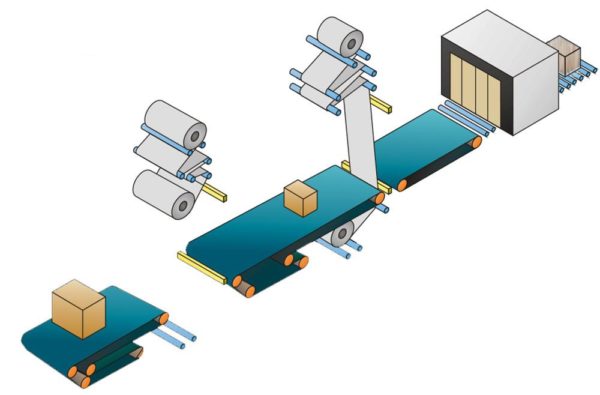

The COMBO is a heated packaging machine that is composed of different modules, each of which has a different sized polyethylene shrink film reel. When a package is placed on the conveyor belt or conveyor table, the machine automatically detects its size and directs it to the module with the most suitable film reel for its dimensions. The product is wrapped with the shrink film and directed to the shrink tunnel, where heat is applied and we obtain a completely packaged product protected from external agents. Immediately afterwards, a package with other dimensions can start this process without having to stop the machine to change the film reel.

No. This is precisely one of the strengths of the COMBO: it allows to pack products of different sizes in a convenient, agile and fast way without generating a huge amount of film waste. The COMBO is capable of automatically detecting the size of the package or product to be packaged and manages it from the part of the machine that has a reel of shrink film of a size more similar to that of the package. This keeps the amount of film waste to a minimum.

CMB’s COMBO packaging machine works with heat shrink film. It is a 100% recyclable polyethylene film whose main feature is that it shrinks when heat is applied to it. This shrinkage allows it to acquire the shape of the package or product it covers, thus achieving an efficient layer of protection, as if it were a skin or film.

If in your company you need to pack products of different sizes and you want to do it with a certain agility, without having to change the film reel depending on the size of the package, the heat wrapping machine you need is the COMBO. This machine is precisely designed for these circumstances: to pack products of different sizes without having to change rolls and, at the same time, without having to dispose of large quantities of film.