The day-to-day running of a company is very demanding. Between working to respond to the needs of customers in an optimal way, managing internal logistics, stocking the necessary materials to be productive, coordinating sales efforts and planning the strategy that will define the future roadmap, there is little time left for the rest. When the day-to-day is so overwhelming, it is difficult to find a moment to sit back, reflect and realise what has been achieved and savour the good times after the bumps successfully surfed.

However, it is important to take a few moments to look back and that is precisely what we at CMB want to do in this article with Juan Barberán, the owner of the company. We want to share with you our history: our best moments and also those in which it was difficult to stand the shaking legs and move forward. It all started in 1986 and it has not been easy.

The family locksmith’s shop was where it all began

“My grandfather had a locksmith’s shop for building sites and he also shoed horses, which was his first trade. The small family locksmith’s shop gave way to a company dedicated to the manufacture of machinery for surface finishing in the wood and furniture sector and which, today, is a world leader with the second generation at the helm. It was precisely in this company that Juan learned most of the things that were of great help to him in promoting and managing CMB. “These years were a very valuable learning experience, even more than some of the subjects he had been studying. In the family business he did everything, he was involved in all departments and played all roles. He started helping the workshop workers who moulded the sheet metal on the bending machines, learned to cut steel with the different machines and tools, welded iron, had to learn to read production plans and, when he knew the company in detail and with precision, he also worked as a salesman. Playing all the roles on the construction site is the greatest apprenticeship there is to be a good manager, and even so, one runs the risk of sometimes getting it wrong.

Like all beginnings, it was not easy

Juan had always been attracted by the idea of creating machines, “but it was clear to me that it had to be something that did not compete with what was already being manufactured in the family business”. When he returned from military service, at a family meeting, he expressed his desire to start something new, and together they thought it would be a good idea to enter the packaging machinery sector. And it was then, in 1986, when CMB (CONST. MET. JOSÉ BARBERÁN, S.A.) was born, a company that took its first steps in the small workshop where his grandfather Juan Barberán Borraz started.

“The beginnings were hard, they always are. However, being able to grow and go hand in hand with the family business was a great good fortune. The teachings provided by his father, José, and his uncle, Jesús, were essential to launch the company that had just been created. In its second year of life, CMB was already present at international fairs such as Hannover, the world’s most important fair for the woodworking, furniture and packaging machinery sector. “Thanks to the advice received from my uncle and my father, managers of the other family business, the international expansion of CMB was achieved shortly after its birth. “Participating in these international fairs allowed us to grow much faster than if we had just visited fairs in our country without going abroad.

Trial and error, over and over again

The first packaging machine manufactured at CMB was a stretch film packaging machine, called the ERL 30, designed for packaging mouldings. “We saw a machine at a trade fair that performed a totally different function but we had the idea of reinventing it to suit what we thought moulding and profile manufacturers needed and the idea worked like a charm. We worked very hard to improve and optimise the operation and performance of that machine to make it suitable for its new role and in the end it turned out to be one of the best that was being manufactured at the time for the packaging of these types of products”.

In the 1990s, CMB wanted to provide a new response to a need that was appearing in an expanding world market due to the increase in demand for furniture, which forced manufacturers to increase production and reduce the delivery times of their products as much as possible. Those companies that had to pack products of different sizes quickly, efficiently and quickly did not have the means to do so adequately and cost-effectively at the same time, as they were wasting large quantities of surplus film. “We saw an opportunity in this market need and created a prototype of an automatic machine for shrink packaging, which we called COMBO.

It didn’t work out… They failed in that design and lost a huge amount of money on that investment. “With such bad luck that some Italians saw our machine, detected what was wrong and corrected it”. Even so, at CMB, resilient, they did not give up and continued working tirelessly until they succeeded after having suffered such an important economic setback. They succeeded. Today, they are proud to say that their COMBO automatic machine is probably the fastest machine on the world market for packaging medium and large packs, without having to change the width of the film reels it uses.

Rigorous and disciplined work that was able to astonish the demanding German market

In the late 1990s, CMB started working closely with several German distributors and customers. “They saw one of our machines at the machinery fair in Valencia and liked it. The German market is characterised by high standards and perfectionism. It is a market with companies that find it difficult to establish synergies if it is not with a company that perfectly matches their standards of quality, service and trust. CMB has achieved this and three decades later continues to do so: it has been working for more than thirty years with leading German companies in the woodworking and furniture machinery sector, and collaborating closely with the most important German distributor of this type of machinery in the world.

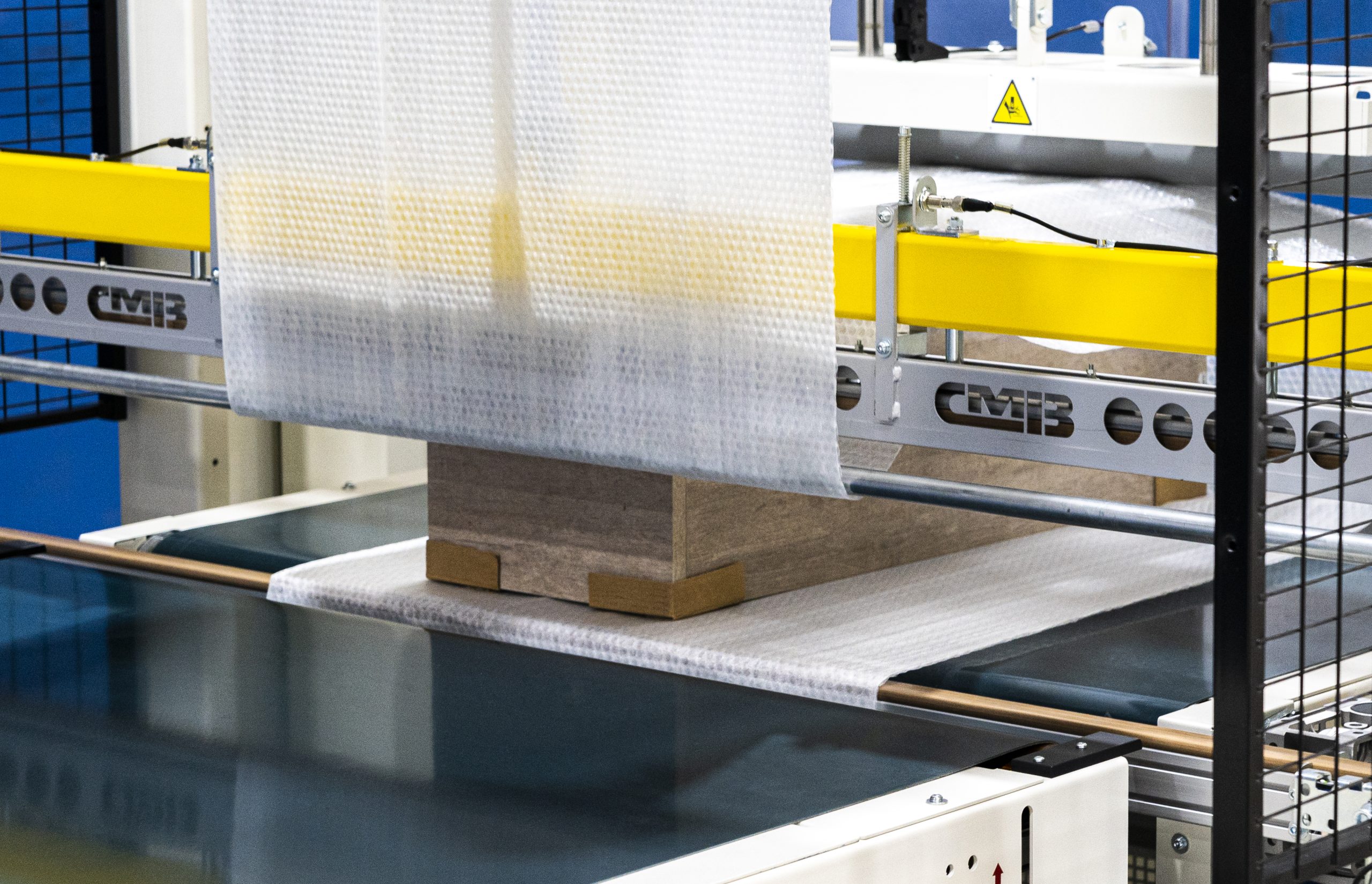

From the ERL-30 to a catalogue of 6 different machines

The first machine to be manufactured at CMB was the ERL-30, a machine from the ERL Series that cold packs using polyethylene stretch film. This was followed by five more series, three cold packers and three hot packers. One of CMB’s distinguishing features is its ability to adapt all these machine models to the customer’s needs to make them even more functional and adapted to the products to be packaged.

Customers who opt for one of the machines from the various series designed and engineered by CMB are more than satisfied with the performance they receive. Machines manufactured by CMB have a well-deserved reputation for being tough and reliable. They never let you down. And there is no better prescription or advertisement than a satisfied customer. This, coupled with the general euphoria of the markets in the period 2000-2007, meant that recently CMB still remembers working with waiting lists that sometimes exceeded 40 machines. “A customer would call us and we would tell him, much to our regret, that he would have to wait up to 10 or 12 months to get his machine, and he would wait. That was not normal, sooner or later it had to explode”. And so it did, with the 2008 crisis, the real estate bubble burst, the construction market stopped dead in its tracks and CMB had to reinvent itself to survive.

Rely on CMB’s Packaging Machinery

If you want to opt for a packaging machine that allows you to protect your products and, at the same time, make a responsible use of consumables, take a look at our catalog. If you have any questions, our sales department will be happy to answer them. We are at your disposal.