CMB: Packaging solutions for all kind of products and companies

In the previous post we talked about the types of cool packaging solutions. Remember that we offer three different methods: Coolpack, ERL o Super P.

Today we want to show you our hot packaging solutions, where we also have three different systems, all of them with excellent results depending on the customer’s needs.

Hot packaging solutions

ERB-Shrink Wrapping Machine: the finishing of a product reflects its quality

This is a method that consists on wrapping products with polyethylene, currently the most recyclable and eco-friendly film. This film allows to have good visibility of the interior and an esthetic and high-quality finish without forgetting that it allows to obtain a high production at a competitive cost. It offers the possibility to finish the product with customized polyethylene films with the logo of your company or with a specific color.

Its advantages are based on two key points: a high production due to the fact that the product only stops once during all the packaging process; and the strength and liability, which is translated into an important save when it comes to maintenance and set-up of the machinery that forms our Hot Packaging lines.

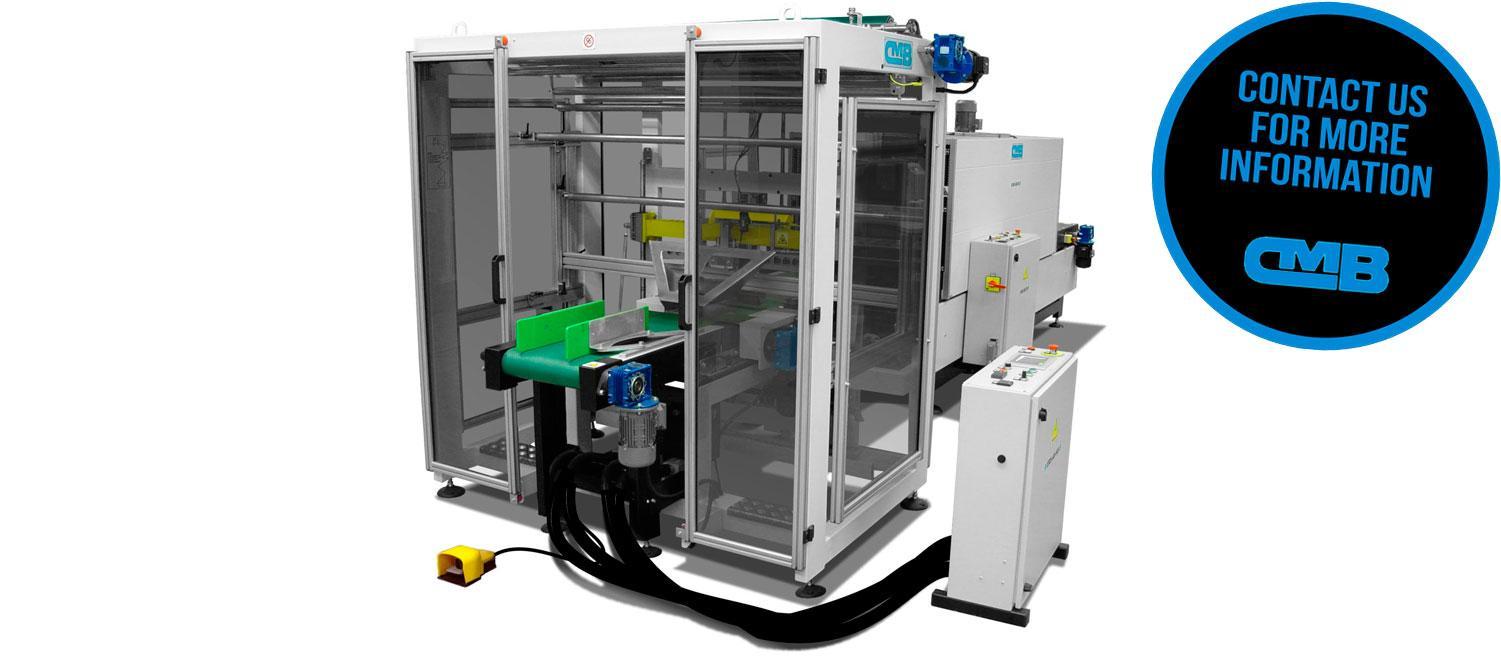

COMBO system: it can beat them all… Non Stop.

COMBO is the fastest automatic packaging facility for medium and big size products of the market.

COMBO packaging systems are perfect when there is a need to work with different size products in the same packaging line. The strong point of this modern system is that it detects the dimensions of the product that is going to be wrapped and it selects the appropriate film spool. This avoids having a big film excess and also saves time as there is no need to change the film spool.

ERS-Shrink Wrapping Overlap machine: maximum visualization and production

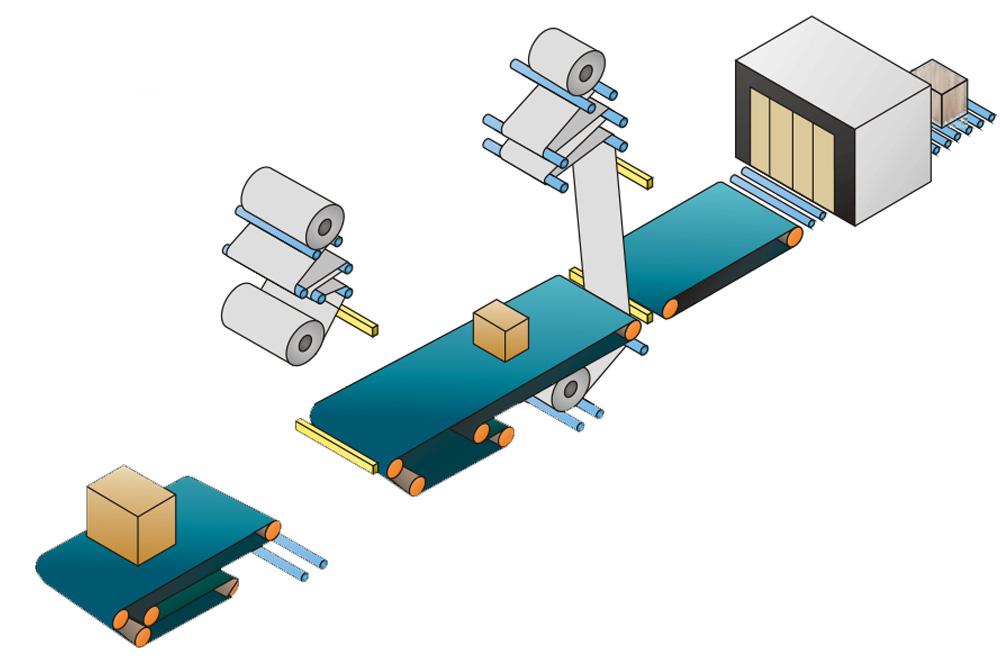

ERS means perfect finish. In this case we talk about an automatic wrapping machine for shrink film that uses lower overlap. The system is composed by an infeed conveyor, sealing bar station that includes metal shoe element for shaping film, intermediary conveyor and heat tunnel.

It is a perfect packaging installation for big productions because it only stops once during the process. The maintenance needed is minimum related to the finish obtained and the robustness and liability that offers.

Remember that if you have any doubt about it or you still don’t know which is the best installation for you, contact us and we will answer all your questions. Don’t forget we are here to serve you and your company!