Uses and applications of bubble wrap for packaging

Recyclable polyethylene bubble packaging film, also known as honeycomb film, is the most widely used system in the world for wrapping, immobilizing and protecting any object during transport or storage.

It is versatile and economical and is never missing from small and large packages in major logistics distribution centres. Bubble wrap is particularly suitable for fragile or valuable products and is widely used in all types of transport, including removals.

What does bubble wrap consist of?

It consists of a recyclable polyethylene film with air bubbles that have an irreplaceable cushioning action. It adapts to all packaging and professional packaging needs, as it can be manufactured in different weights, with micro-bubble or large bubble, in reels, pre-cut rolls, sheets, sachets, and tubes. Furthermore, it is economical, lightweight and 100% recyclable.

Which CMB machine works with bubble film for packaging?

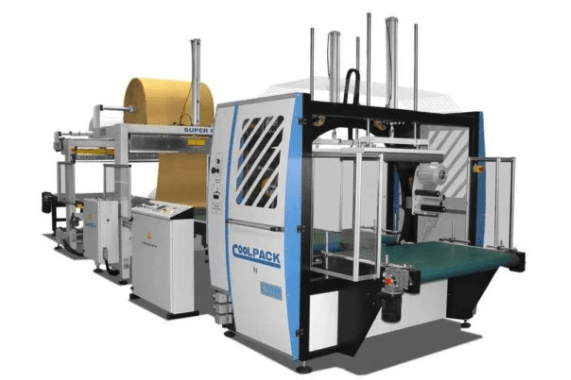

CMB has a very versatile packaging machine from its COOLPACK Series line that has the particularity of combining bubble packaging film and stretch film to achieve high protection with very low-energy and material consumption. Both films are of the polyethylene type and fully recyclable.

This packaging system is ideal for the secure packaging of non-standard sized products that require special protection, such as doors, windows, furniture, where it is essential, for example, to pay special attention to corners, edges, or glass. In fact, it is one of the most widely used types of packaging in the wood, aluminium, and PVC industry.

The system combines the two materials, offering double and complementary insulation: the protection of the bubble and the fixing effect of the stretch film.

This model of packaging machine is effortless to use, flexible and efficient. As it does not use a heat source like the traditional shrink wrap system, it is effortless to set up and get up and running quickly and very economical in terms of energy costs, which contributes to reducing our carbon footprint. What’s more, it can even incorporate specific packaging consumption reduction software to optimize the process. It does not require extensive maintenance, making it an ideal machine for high protection packaging.

COOLPACK Series, its models, ranges, and features

CMB’s COOLPACK family of packaging machines can pack medium to large pieces, being with the latter where the machine is more comfortable working, thus achieving the excellent finishes that already characterize it in the market.

The packaging process with the COOLPACK models

The packaging process is basic in all models of the COOLPACK Series. The product to be packaged is transported by a table with a motorized belt to a high-performance sealing head, which also houses the cutting station.

The bubble film covers the top and bottom of the product to be packed, creating a kind of bag, which is then closed at the front and rear edges by the sealing head.

After closing, it continues its passage to an intermediate station towards a rotating crown, where the stretch film will make a spiral bandage that will be cut automatically at the end.

With this last action, the packer is again ready to start a new process. CMB designed packaging machines can work in line or as stand-alone packers.

Get your cold packaging machinery at CMB

With these packaging developments, CMB is at the forefront of robotic and automated solutions, able to work with different materials that you can select according to the specific needs of your product: stretch film, bubble film or both combined.

You can rely on CMB, an exporting company with more than 30 years of experience, which works generating value and branding in all continents, together with constant research and participation in international fairs and congresses.

We will be pleased to help you with our packaging solutions. You can simply fill in the form in our contact section, call us on (+34) 93 636 14 16 or email us to [email protected].