At CMB you will find special machinery for wrapping doors, both for cool and hot wrapping

In terms of door wrapping machines, at CMB, as experts in the packaging of all types of medium and large furniture and products made of wood or other materials, we have two different models that we usually recommend, both to work cold and with heat, depending on customers’ production requirements.

A tremendously efficient door wrapping machine with a high degree of superlative protection with the most affordable and competitive packaging cost on the market

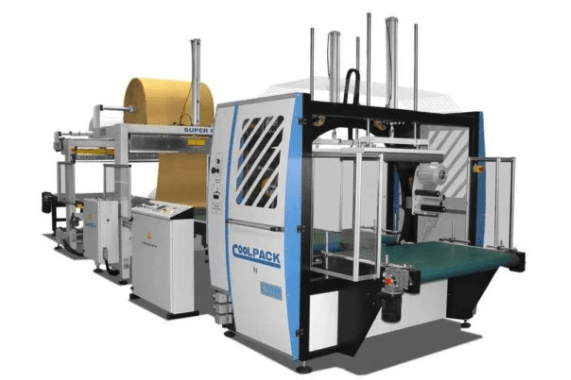

The first machine we would like to show you is our COOLPACK door wrapping machine, for cold working and ideal for doors and all types of furniture, home accessories, windows…. It is a machine with a controlled production capacity, which combines a high degree of protection with a low cost of electricity consumption, thereby achieving an excellent protection in terms of the materials used and with a very low energy consumption.

Its design and system are especially designed for products that require a special degree of protection. Its strength lies in the fact that it is capable of combining recyclable polyethylene bubble film with recyclable polyethylene stretch film, providing a double insulation, based on the mixture of the cushioning effect of the bubble with its air capsules and the strong and reliable hold provided by the stretch film.

Furthermore, we are looking at a highly versatile installation with a great deal of flexibility, since it is capable of packaging a wide variety of sizes, being extremely effective, efficient, profitable and affordable in terms of energy consumption.

The ERB door wrapping machine: the best finishes, along with a high production

An extremely wide range of products can be protected with this door wrapping machine for working with heat: all types of furniture, wood, mattresses, textiles, profiles and fencing, vehicle accessories…

Our specific models for packaging doors are the most highly reliable and productive on today’s market.

Depending on the model chosen, it provides an exceptionally high production capacity since it only makes a brief stop to weld the film during the entire packaging process. In our transversal working model, the production capacity increases to remarkable limits.

In addition, it also offers the option of finishing the packaging of the products with customised finishes, using recyclable polyethylene films with specific characteristics, colours, or even with the brand’s printed logo.

This is a shrink wrapping machine characterised for its excellent strength and high degree of reliability, which means a significant saving in maintenance and servicing, apart from having a fast and simple installation.

Other interesting stations for applying protective materials to incorporate into our automated wrapping machines from our catalogue: practically unlimited protection of the SUPER P model

Adding the SUPER P model to our wrapping machines enables an automated system capable of offering an even higher degree of protection, along with its extremely high quality aesthetic finishes in the packaging; this is industrial machinery with advanced technology that reaches rates of energy efficiency never seen before and that can combine a multitude of packaging materials in overlapping layers, achieving a superior protection for the packaged material, a factor that improves the features of our wrapping machines, making them even more eco-friendly and profitable.

This model has been designed to achieve two types of wrapping; completely wrapping the product and enclosing it with stretch film at the end of the process, or only packaging the upper surface – the front and rear parts are also protected- also finishing with stretch film and achieving a highly protective final packaging, while maintaining the significant energy saving since they are optimised systems that work with minimum energy input without harming the efficiency of the packaging processes of the products.

Contact our sales department to receive all of the information in more detail

These wrapping machines represent a considerable, yet highly profitable, investment for most companies in our country. Our breadth of experience has shown us that these machines usually generate certain queries if you don’t have an in-depth knowledge of the sector or specific applications of each model.

If you need to contact us, you just need to send us an email to [email protected], call by telephone on (+34) 93 636 14 16 or complete the form that you will find on this website.

We have spent more than thirty years committed to the research and development of new technologies for the industrial packaging of wood products, furniture and other materials, always respecting the environment and its conservation.

We have extensive know-how of everything relating to the optimisation of packaging plants for these types of products and, without a doubt, this is the best guarantee for each of our customers.

We will study your packaging requirements in depth and our team of specialist technicians will suggest the most suitable model to automate your plant for the packaging of your products.

In general, all of our machinery has been designed to optimise productivity, profitability, improve energy efficiency and increase the safety of modern packaging plants, which can provide a high value to your company.

Bear in mind that, over the more than thirty years that we have worked in this sector, we have exported our technology and installed our machines around the world, helping to grow and improve a long list of companies, mainly in the wood and aluminium sector, among others.

Our relationship never ends with the sale; you will have an excellent technical support and after-sale service, the best professionals and the most advanced machinery on the current market.