The best option on the market for this type of packaging is our automatic packaging machine for profiles and mouldings

With the ERL-30 Express we have manufactured a stretch wrapping machine with guaranteed profitability, very high energy efficiency and a packaging system designed to achieve maximum production with minimum added cost to the product. You can find this model of machine at several of our customers’ facilities, and while they have packed over a million packages, our ERL-30 is still running as good as new. It is extremely reliable, with a bearing system that is used in the aeronautical industry.

In essence, it is an automatic machine specially designed for packaging profiles and mouldings, with a rotating head that wraps with stretch film as if it were “bandaging” the part being packaged. The machine has been specifically designed for the wrapping of all types of mouldings and profiles, be it wood, aluminium or PVC, and is particularly suitable for wrapping this type of product at a high speed, resulting in a perfectly secured and wrapped package, and at a minimum cost, due to the use of recyclable polyethylene film in the stretching process. The longer the length of the packages are, the better all the systems installed on it will work.

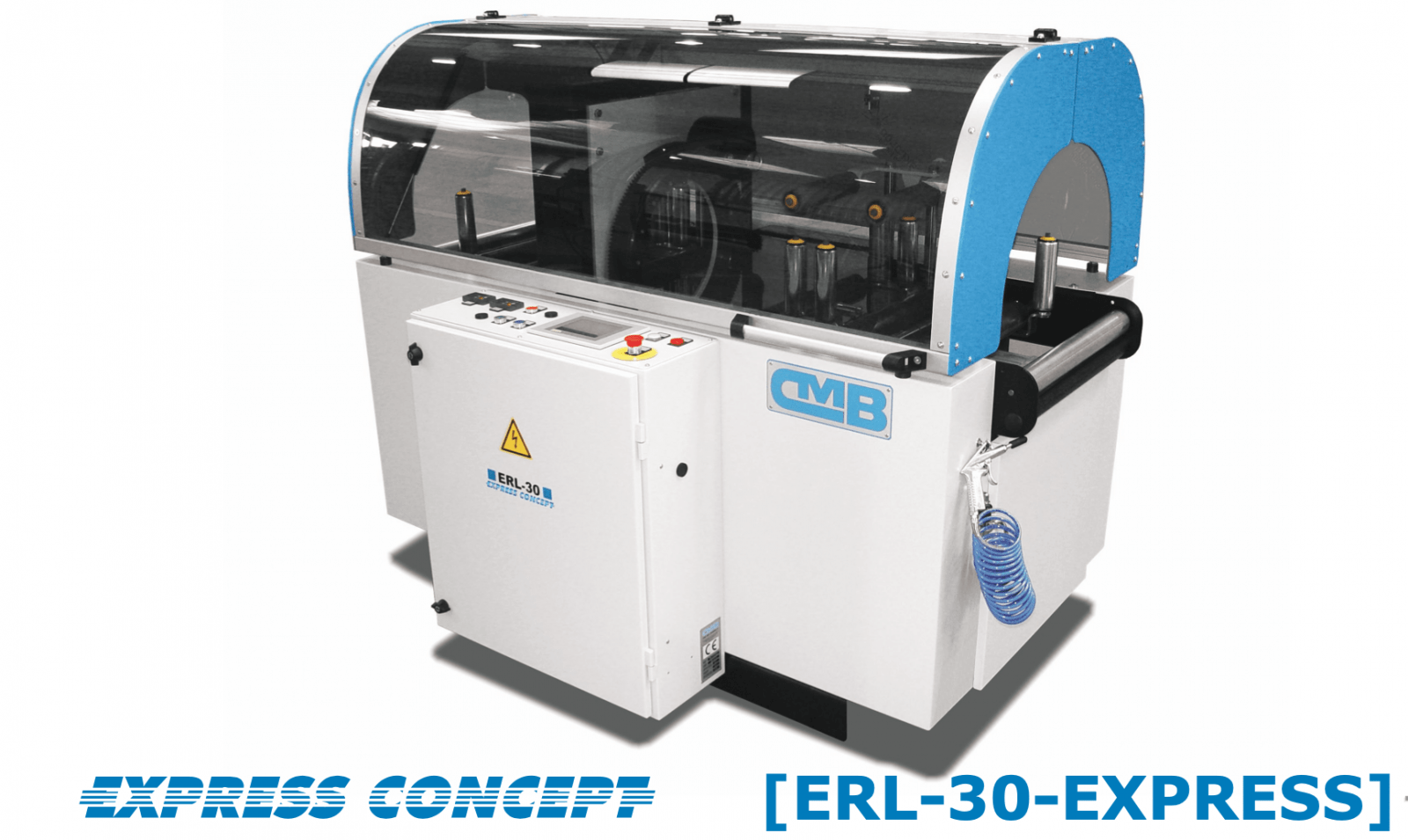

The ERL-30 EXPRESS CONCEPT is a compact machine which includes an infeed table with motorised castors to insert the package into the rotary crown, which can be made of steel or rubberised steel, a central body with a wrap-around rotary crown with its built-in film cutting system, and an outfeed table also with motorised castors to help remove the wrapped package.

The product is placed on the infeed table, and after the vertical castors have been adjusted, it is followed until the product is picked up by the motorised castors and the machine automatically carries out the entire packaging process, with the pre-set adjustments and including the automatic cutting of the film on each wrapped product.

Specially designed for profiles and mouldings made of wood, aluminium, PVC, or any other material.

Due to its high-speed features, this machine is strongly recommended for high production outputs and in production facilities that require a high level of operational reliability.

Among its noteworthy technical characteristics is its wrap-around gear rim, designed for maximum performance and reliability, with internal elements that are also used in the aeronautical industry. It is the only machine on the market that uses this system, making it the most reliable machine for this type of work. The monobloc construction also makes all installation and relocation tasks much easier.

Why go for automated packaging with the ERL 30 Express Concept wrapper?

Opting for this model of stretch wrapper will reap a long list of benefits for your plant. Firstly, the low cost of consumables and maintenance makes this machine ideal for any industrial sector. The film stretching mechanism maximises the use of the film and at the same time ensures that all the pieces that make up the wrapped packages are perfectly secured to each other. Its tightening capacity is so high that it is sometimes unnecessary for the packages to be strapped, since the stretch film, when properly tightened, is more than enough and, as an additional advantage, the final product is perfectly packaged, something that cannot be achieved with strapping alone. Its packaging system lets you work continuously with various sizes of packages, with the maximum length you require. The equipment is safe and easy to use, which saves operators long adjustment and training periods, while at the same time greatly increasing both the quality of the end result and safety at work, with all that this entails for any company.

It offers excellent packaging results for blinds, profiles, tubes, mouldings, flooring… protecting them from dust and dirt, and creating compact and attractive packaging that showcases the product. The packaging process using recyclable polyethylene stretch film is much more economical than that of heat-shrink film, due to the much lower energy consumption and the fact that the size of the reel does not need to be adjusted to the product being packaged. A wrapping machine designed to increase productivity and reduce costs simultaneously, working with recyclable polyethylene material to help protect the environment and ensure the best possible quality final packaging.

Other CMB machinery you may be interested in to optimise your packaging plant

CMB has over 30 years of extensive experience in the design and manufacture of packaging machinery, with a strong commitment to innovation and the development of new technologies and materials, all the while respecting the environment and minimising, as far as possible, the carbon footprint of our machine activity. As a result, we have a comprehensive catalogue of state-of-the-art packaging equipment and systems available, specially designed to optimise an industrial and highly profitable production line for our customers.

You will see that we have machinery for working with both cold and hot systems, and also with different materials such as polyethylene stretch film, bubble wrap, recycled film and now also with KRAFT paper – the latter is one of the latest innovations in our machinery, the particular machine designed for working with this material is called COOLPACK KF –.

As far as cold packaging is concerned, apart from the ERL, which is the machine that works only with stretch film, we have the COOLPACK SERIES with stretch film and bubble wrap, and a complementary unit called SUPER-P, which gives your packaging a lot of extra protection by applying sheets of corrugated cardboard.

If you require heat shrink machines for the final touches of your product , we have three different models of shrink systems: the ERB Series shrink wrappers, the ERS Series shrink wrappers and the COMBO Series premium system, all of them with different applications and features, yet sharing some common factors: high quality in packaging processes, higher productivity, maximum energy efficiency, and very easy to use.

To request a quote or detailed information, simply fill in the form in our contact section, call us on (+34) 93 636 14 16 or send an e-mail to [email protected].

We will answer all your questions, provide you with a friendly and personalised service, and find the machine that best suits the needs of your packaging plant.